Home > CO2 Heat Pumps & Chillers

The Most Sensible Solutions for Meeting This Moment

R744 (CO2) Heat Pumps & Chillers for Demanding Commercial, Industrial, and District Energy Applications

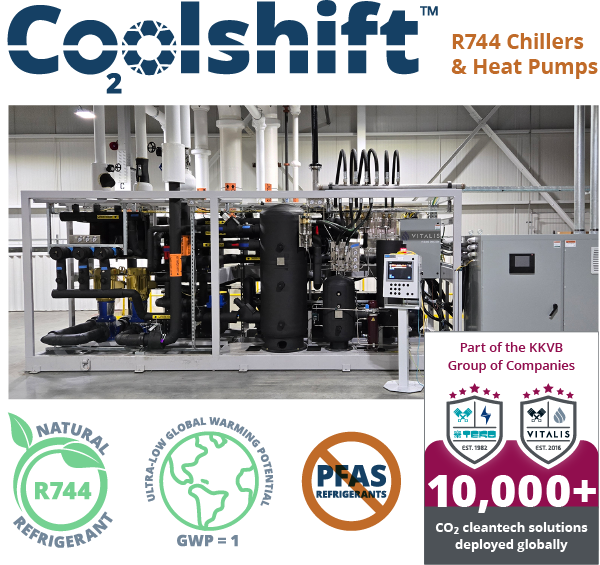

In an era defined by climate urgency, regulatory pressures, and economic volatility, businesses and communities need efficient, reliable, future-proof, and environmentally responsible heating and cooling solutions. Vitalis Coolshift™ R744 heat pumps and chillers offer excellent performance without the harms of F-gas refrigerant systems. Built to last and backed by expert customization and application engineering support, Coolshift systems help you reduce emissions, minimize operating costs, and adapt with confidence.

Versatile Solutions, Countless Possibilities

Thanks to the flexibility of our core technologies, Vitalis Coolshift R744 systems can be used across a wide variety of different sectors. They excel in demanding environments requiring continuous heating or cooling (or both simultaneously).

Vitalis Coolshift water-to-water R744 heat pump, currently the largest of its kind in North America, used for an industrial process requiring simultaneous heating and cooling in Michigan. It can move up to 2.5 MW of thermal energy (1.5 MW of heating and 1 MW of cooling).

Vitalis Coolshift R744 system used for chilling a large spiral freezer at a food manufacturing facility in Texas.

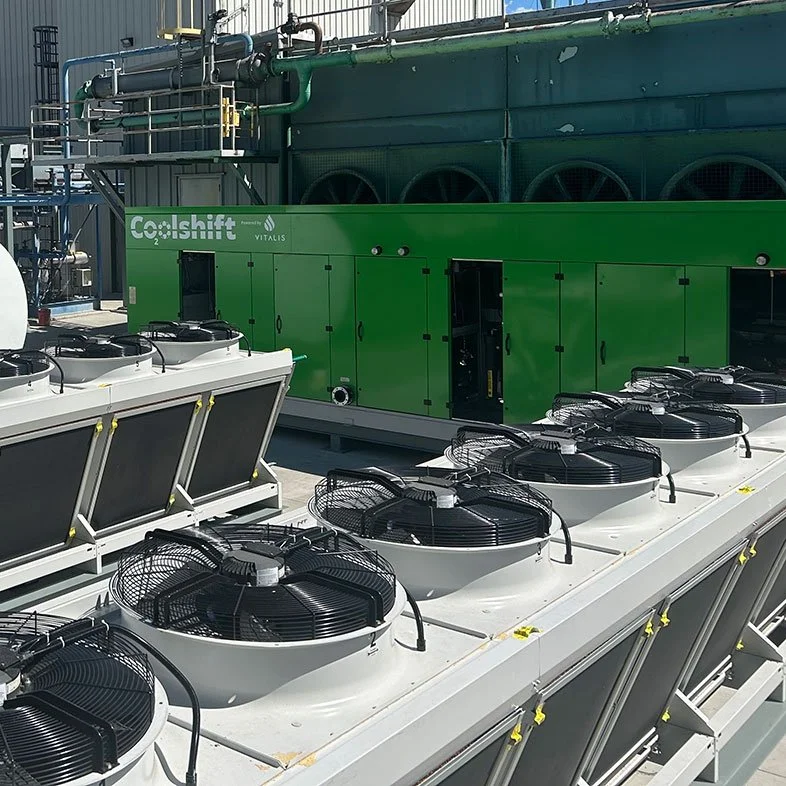

300 TR (1,050 kW) Vitalis Coolshift air-cooled R744 industrial chiller, with heat reclaim capability, for a large CO2 extraction system in Washington.

-

Industrial Processes

Breweries

Distilleries

Dairies

Battery Plants

Food Manufacturing

Automotive Facilities

Pharmaceutical Manufacturing -

Industrial Cold Storage

Food & Beverage

Pharmaceuticals

Agriculture

Chemicals

Retail/Wholesale Distribution

Logistics -

Large-Building HVAC

Hospitals

Hotels

Recreation Facilities

Office & Residential High-Rises

Malls

Warehouses

Airports

Event Centres -

District Energy Systems

Municipalities

College/University Campuses

Multi-Building Developments

Advanced Customization: The Right Fit for Your Project

Single-rack configurations of 50 kWt to 3 MWt, depending on application

Get instant access to all operating information with an integrated control platform.

Vitalis Coolshift systems are available in a range of configurations, for indoor or outdoor installation. Our team works with you to tailor the system design to your specific needs, supported by expert application engineering and integration with your existing infrastructure. We consider variables such as:

Capacity

Supply and return temperatures

Ambient temperatures

Heat recovery options

Physical space constraints

Power supplies

Integration with other equipment, industrial control platforms, or building automation systems

Local regulations

Configuration Options

-

Air to Water

-

Water to Water

-

Air to Air

-

Air-Cooled or Water-Cooled

-

Reversible

-

Dedicated Hot or Cold

-

Combined Heating & Cooling

-

DX

-

Liquid Overfeed

-

Well-suited for applications requiring year-round operation

-

Ideal for applications requiring high supply temperatures (up to 90°C/194°F), large temperature differences, efficient hot water generation, and waste heat recovery and utilization

Built for Reliability, Engineered for Endurance

Durability isn’t optional. Vitalis Coolshift systems are engineered with precision and built using robust materials. Designed for continuous operation in demanding environments, they deliver consistent performance with minimal maintenance.

-

Stainless steel welded piping

-

Integrated SCADA system

-

Simplified oil management

-

Redundant filter driers

-

Continual process optimization

High Efficiency for Serious Energy Savings

Vitalis Coolshift systems can achieve a high coefficient of performance (COP) and are well-suited to applications with low ambient temperatures and low return water temperatures. Compared to other refrigerants, R744 enables a greater temperature difference between supply and return.

Coolshift systems deliver unmatched efficiency when the return temperature is below 49°C (120°F) or when the temperature difference between supply and return exceeds 30°C (54°F) for applications requiring supply temperatures below 90°C (194°F).

This graph summarizes operating conditions and how R744 (CO2) can handle different source and sink temperatures in terms of performance and complexity.

The horizontal-axis represents the heat source temperature, while the vertical-axis represents the heat sink temperature. As shown here, a CO2 heat pump can deliver water temperatures as high as 90°C (194°F) for heating while absorbing heat from a source with temperatures as low as -5°C (23°F).

At the bottom of the graph, a straight rectangular region indicates return temperatures below 35°C (95°F). In this region, the CO2 heat pump operates with a simple transcritical cycle and a flash gas bypass. This configuration can be very efficient, delivering water temperatures up to 90°C (194°F), with a COP ranging from 2 to 9 depending on the source temperature.

However, when return temperatures exceed 35°C (95°F), additional components are required to improve the COP, making the system more complex. In such cases, the system may use a transcritical cycle with parallel compression or a mechanical subcooling to manage the extra flash gas generated. The COP in this case can vary from 1.5 to 4, depending on the source temperature.

When the source temperature is very low and high supply temperatures are required, or when return temperatures exceed 35°C (95°F), a dual-stage system (such as a cascade or booster system) is needed.

When a low supply temperature is required, below 25°C (78°F or 80°F), such as for conditioning an ambient loop district energy system, the CO2 heat pump operates in a subcritical cycle. In this scenario, the COP can vary from 2.5 to 10 depending on the source temperature.

Coolshift™ Chiller Package for Breweries, Dairies, and Glycol Cooling Systems

Lower your operating costs and gain more freedom to play.

This energy-efficient solution utilizes an R744 heat pump for your process cooling and is supplied standard with a heat recovery package. Use it to chill your glycol loop for process cooling and temperature control. Reduce your energy and operating costs by recovering the heat from chilling for hot water or steam production. (Replace the need for inefficient stand-alone chillers and boilers.)

Each standard package includes:

Heat recovery solution

SCADA system for seamless integration and continuous optimization

Compatibility with Vitalis Freecovery™ carbon capture system

With the optional Freecovery carbon capture integration, you can recover CO2 from your fermentation and store it. It's your own supply of CO2, made accessible. No more worrying about shortages. The Freecovery system reduces your operating costs and the overall carbon intensity of your product manufacturing.

Other options include:

Steam generation

Air cooling

Hot water (80°C+)

Water storage on skid (1,500–10,000 L)

Campus Decarbonization, Accelerated

As a growing campus, the University of British Columbia Okanagan (UBCO) is facing the challenge of meeting increasing heating and cooling demands while also trying to achieve aggressive decarbonization goals. For its newer buildings, the campus uses a low-temperature district energy system (LDES), which relied heavily on gas boilers for heating. In an effort to reduce greenhouse gas emissions, the university sought to displace its boilers with sustainable heat pump technology.

The installation of a Vitalis Coolshift reversible R744 air-source heat pump (ASHP) is expected to deliver over 98 percent of the LDES' total heating demand in subcritical mode, lower greenhouse gas emissions by about 815 tonnes per year, and displace 430,000 cubic meters of natural gas annually. The heat pump, with a nominal capacity of 1.5 MW at -10°C, can operate between outdoor temperatures of -20°C and 40°C. In the summer, the system will provide auxiliary cooling to the LDES. It is designed to deliver an annual coefficient of performance (COP) of 3.5 for heating and 3.6 for cooling. With an upgrade path capable of providing 2.5 MW of capacity, this system is currently the largest reversible R744 ASHP in North America.

How does a Vitalis Coolshift™ heat pump work?

(Example shown is for a brewery application.)

Heat is absorbed in the Evaporating HX (heat exchanger), where the CO2 (R744) changes from liquid to vapor.

The CO2 compressor increases the pressure and temperature of the vaporous CO2.

Heat is rejected in the Condensing HX, where the CO2 changes from vapor to liquid before moving into the high-pressure CO2 Receiver.

The Expansion Valve lowers the pressure and temperature of the liquid CO2.

Process cooling is achieved by circulating your heat transfer fluid through the Evaporating HX.

Process heating is achieved by circulating your heat transfer fluid through the Condensing HX.

An optional Steam-Generating Heat Pump can utilize waste heat from the hot HTF loop and increase the temperature of heated water from 90°C to 150°C.

Why Vitalis?

Our mastery of application engineering serves as a foundation for our ability to develop innovative systems that take advantage of carbon dioxide's unique properties. That proficiency is validated in closed-loop Vitalis systems that:

Use CO2 for the extraction of natural ingredients from biomass

Employ CO2 as a heat transfer fluid (HTF)

Utilize CO2 as a natural refrigerant

Recover and recycle CO2 for repeated use

As a vertically integrated original equipment manufacturer (OEM), we manufacture all major components. And we leverage our wealth of R&D, design, engineering, production, and support experience to deliver reliable and responsible solutions across multiple industries.

As part of the KKVB Group, we benefit from global collaboration and knowledge exchange with our sister companies, TEKO and Frigopol. Through joint development projects and technology transfer, teams from all three companies work closely together. We are collaborating to meet the growing demand for R744 systems with:

Improved quality

Automated quality inspection and leak detection

Audited quality systems in place

Increased reliability

Reducing component failures through rigorous testing

Leveraging TEKO implementation and R&D excellence

Industrial control platforms (model-specific)

Lower costs & higher performance

Reducing component count

Automated manufacturing/tooling

Application engineering support

A clean world is possible, and business will help take us there. We're committing our proven expertise in CO2 handling to the cause of collective resilience and thriving. Vitalis technologies help sustain the lives of companies and communities as we co-create a decarbonized and detoxified future for all.

Get Ahead of What's Inevitable

Let's talk about future-proofing your business or community with a chiller or heat pump designed for performance and longevity.

Are you an HVAC/R distributor or manufacturers’ representative?

Talk to us about adding R744 solutions from Vitalis to what you offer.