PrimeEx R-600 being assembled for a Canadian customer

CO2 Extraction for Plant Protein Ingredients

The plant-based protein market keeps growing as more and more consumers look for healthy, sustainable alternatives to animal-derived proteins. Product formulators continue to innovate, but they often face challenges with factors like taste and nutritional quality.

For example, in the value-added processing of seeds and legumes for low-fat protein isolate, defatting is an essential step. But conventional methods of oil removal‚ such as hexane extraction, can promote protein denaturation and leave off-flavors and residual solvent in the defatted product.

Using supercritical CO2 for defatting, formulators can achieve neutral taste profiles with a sustainable process that leaves behind no residues, just high-quality protein.

-

Before (left): milled hemp seeds

After (right): defatted hemp seeds -

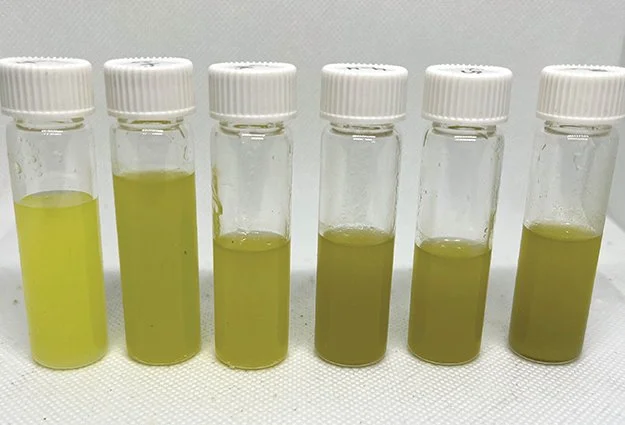

Samples of oil removed from milled hemp seeds over the course of a CO2 extraction run

Highlights

-

Safe, non-toxic defatting that leaves no residual solvent.

-

Suitable for plant protein sources like hemp, soy, peas, canola, faba beans, lentils, and more.

-

Add value to cold pressing by recovering protein from press cakes through residual oil removal.

-

Target undesirable compounds for extraction, such as phospholipids linked to off-flavors.

-

Preserve the quality of extracted oils.